Why Engineering Companies Are Moving Toward Digital Simulation-First Design

Engineering has entered a new era where products are born in virtual space before ever taking physical form. Digital simulation-first design—the practice of creating, testing, and optimizing products entirely through computer modeling before building prototypes—is reshaping how engineering companies innovate. According to the U.S. Department of Energy, companies using simulation-driven design reduce product development costs by 20-30% while cutting time-to-market by up to 50%. The global engineering simulation market is projected to reach $18.5 billion by 2027, reflecting widespread industry adoption. This shift isn’t just about cost savings—it’s about fundamentally rethinking how we bring ideas to life in an increasingly complex, competitive world.

Understanding the Basics

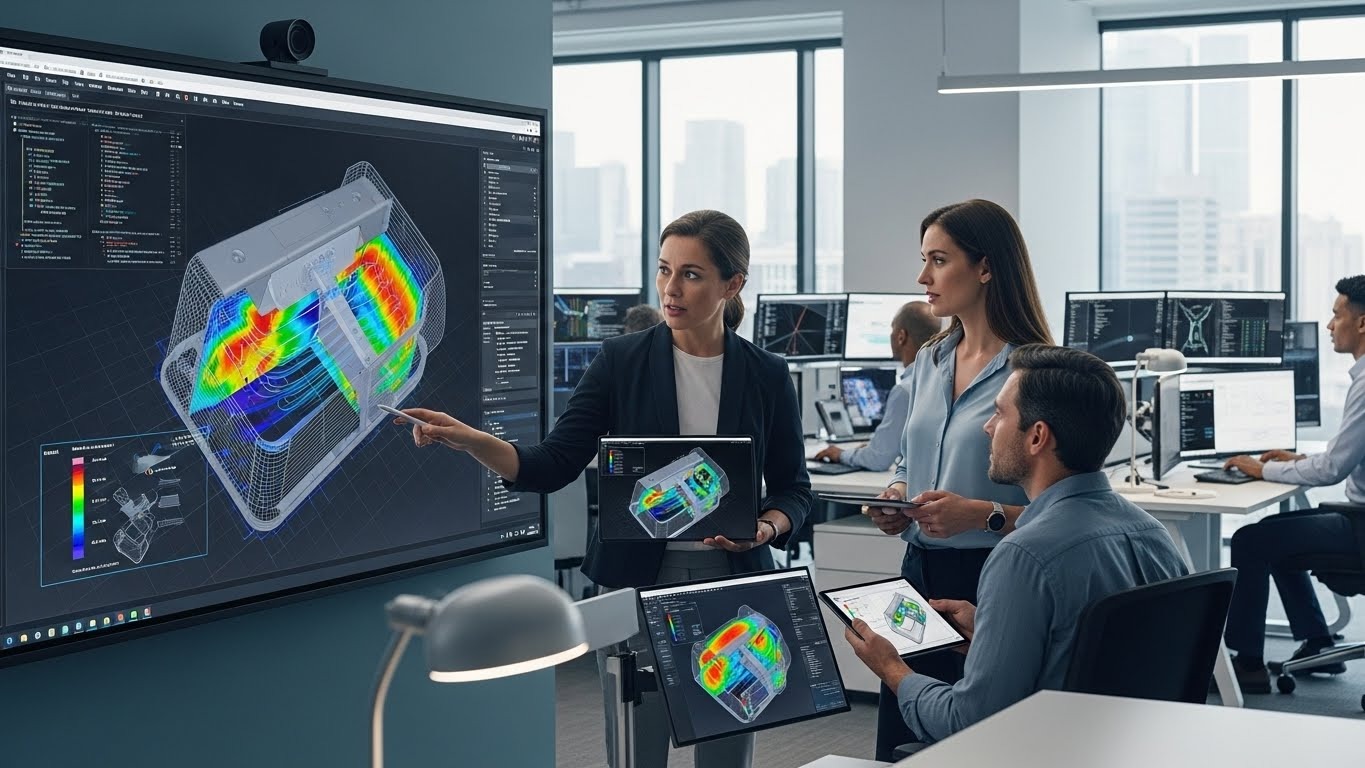

Digital simulation-first design means engineers create complete virtual models of products and test them under realistic conditions before manufacturing begins. Instead of building multiple physical prototypes, teams use computational tools to predict how designs will perform under stress, heat, fluid dynamics, or electromagnetic forces.

Think of it like a flight simulator for pilots. Just as pilots practice emergency scenarios safely on the ground, engineers can crash-test vehicles, stress-test bridge designs, or simulate years of product wear—all digitally. The simulations provide data-rich insights that guide design decisions early when changes are cheapest and fastest to implement.

This approach flips traditional engineering on its head. Rather than “design, build, test, redesign,” the new paradigm is “design, simulate, optimize, then build once.”

Why This Topic Matters

Digital simulation-first design addresses critical challenges facing modern engineering companies:

- Cost reduction: Eliminating multiple physical prototype iterations saves materials, labor, and manufacturing expenses that often run into millions for complex products

- Speed to market: Virtual testing cycles take days instead of weeks, allowing companies to launch products faster and respond quickly to market demands

- Innovation without risk: Engineers can test radical design concepts virtually without the fear of expensive failures, encouraging breakthrough thinking

- Sustainability: Reducing physical prototypes means less material waste, lower energy consumption, and smaller carbon footprints

Consider an automotive manufacturer developing a new electric vehicle. Traditionally, they might build 10-15 physical prototypes at $500,000 each to test aerodynamics, crash safety, thermal management, and performance. With simulation-first design, they run thousands of virtual tests, identify optimal configurations, and build perhaps two physical validation prototypes. That’s a $6.5 million savings before the first customer ever sees the product.

Key Components of Simulation-First Design

Multi-Physics Simulation Platforms

Modern simulation platforms integrate multiple physical phenomena simultaneously. Engineers can model how a smartphone chip generates heat, how that heat spreads through materials, how it affects battery performance, and how cooling systems respond—all in one unified simulation.

These platforms use finite element analysis (FEA), computational fluid dynamics (CFD), and electromagnetic modeling to create digital twins that mirror real-world physics. Popular tools include ANSYS, COMSOL, Siemens Simcenter, and Dassault Systèmes’ SIMULIA. The key advantage is seeing how different systems interact, which often reveals problems invisible when testing components separately.

Cloud Computing Infrastructure

Simulation-first design demands massive computational power. A single crash test simulation might require processing terabytes of data and running millions of calculations. Cloud computing makes this accessible to companies of all sizes.

Instead of investing millions in on-premise supercomputers, engineering teams rent computing power as needed. AWS, Microsoft Azure, and specialized providers like Rescale offer high-performance computing that scales from small startups to Fortune 500 manufacturers. This democratization means even small engineering firms can run enterprise-grade simulations that were impossible a decade ago.

Design Optimization Algorithms

Beyond simulating existing designs, modern software uses artificial intelligence and machine learning to suggest improvements. Generative design algorithms explore thousands of design variations automatically, identifying solutions engineers might never conceive.

For example, Airbus used generative design with simulation to create an airplane partition that’s 45% lighter than conventional designs while maintaining strength requirements. The algorithm tested 10,000 variations virtually, something impossible through physical prototyping. Common mistakes include over-constraining optimization parameters or not validating AI-suggested designs with engineering judgment—remember that algorithms optimize for defined criteria but may miss practical manufacturing or maintenance considerations.

Practical Tips You Can Apply Today

- Start small with pilot projects: Choose a single product line or component for your first simulation-first initiative rather than attempting company-wide transformation immediately

- Invest in training before software: The best simulation tools are worthless without engineers who understand both the software and the physics being modeled—prioritize skill development

- Create a digital materials library: Build a database of material properties, test data, and validation studies so simulations reflect your actual manufacturing materials accurately

- Establish validation protocols: Always compare early simulation results against physical tests to calibrate your models and build confidence in virtual predictions

- Integrate simulation into design reviews: Make simulation results a required part of design decision meetings, not an afterthought when problems emerge

- Document simulation assumptions: Keep detailed records of boundary conditions, simplifications, and modeling choices so teams can learn from past projects and improve accuracy

Common Mistakes and How to Avoid Them

Treating simulation as perfect truth: Simulations are models—simplified representations of reality. They’re extremely useful but contain assumptions and approximations. Always validate critical simulation predictions with physical testing, especially for safety-critical applications. Use simulation to reduce the number of physical tests, not eliminate them entirely.

Neglecting mesh quality and convergence: Poor simulation setup produces garbage results no matter how powerful your software. Invest time learning proper meshing techniques, checking solution convergence, and understanding when results are trustworthy. A coarse mesh that runs fast but misses critical stress concentrations is worse than useless—it’s dangerous.

Ignoring manufacturing constraints in virtual designs: Simulation-optimized designs sometimes create shapes impossible to manufacture or assemble. Involve manufacturing engineers early in the simulation process and include fabrication constraints in your optimization parameters. The lightest design means nothing if it costs 10 times more to produce.

Underestimating data management needs: Simulation projects generate enormous data volumes—terabytes per project aren’t uncommon. Without proper data management systems, teams waste hours searching for files, lose track of design versions, and can’t reproduce past results. Implement robust PLM (product lifecycle management) systems from day one.

Real Example: GE Aviation’s Jet Engine Development

General Electric Aviation transformed its jet engine development using simulation-first design for the LEAP engine, which powers the Boeing 737 MAX and Airbus A320neo. Traditionally, developing a new jet engine required 5-7 years and dozens of physical engine builds for testing.

For the LEAP program, GE created a comprehensive digital twin simulating combustion, aerodynamics, thermal behavior, and mechanical stresses across 20,000+ components. Engineers ran over 1.5 million hours of computational simulations, testing configurations that would have been impossible to build physically.

The results were remarkable: GE reduced physical engine tests by 50%, cut development time by 18 months, and achieved 15% better fuel efficiency than previous engines. The fuel savings alone translate to over $1 million per aircraft annually for airlines. When the first physical LEAP engine was tested, it performed within 1% of simulation predictions—validating years of virtual development work.

This wasn’t just about software. GE invested heavily in training, built partnerships with supercomputing centers, and created workflows integrating simulation throughout the design process. The lesson: simulation-first design delivers transformational results when treated as a comprehensive strategy, not just a software purchase.

H2: Final Thoughts

Digital simulation-first design represents the future of engineering—a future that’s already arriving at leading companies worldwide. By testing virtually before building physically, engineering teams reduce costs, accelerate innovation, and explore possibilities once considered too risky or expensive.

The transition requires investment in software, computing infrastructure, and most importantly, people with the skills to leverage these tools effectively. Start with pilot projects, validate your models against reality, and gradually expand as your team builds confidence and capability.

The companies thriving in tomorrow’s competitive landscape will be those that master the art of creating, testing, and perfecting products in virtual space. Begin your simulation-first journey today by identifying one product that could benefit from virtual prototyping—the insights and savings will speak for themselves.

FAQs

What types of engineering disciplines benefit most from simulation-first design?

Simulation-first design benefits virtually all engineering disciplines, but sees heaviest adoption in aerospace, automotive, civil engineering, and electronics. Mechanical, structural, thermal, and fluid systems all have mature simulation tools available. Even emerging fields like biomedical engineering and renewable energy increasingly rely on computational modeling before physical prototyping.

How much does it cost to implement simulation-first design in a mid-sized engineering firm?

Costs vary widely based on software licensing, computing infrastructure, and training needs. Entry-level simulation packages start around $10,000-$30,000 annually per seat, while enterprise solutions can reach $100,000+ per license. Cloud computing runs $50-$500 per simulation depending on complexity. Budget $150,000-$500,000 for the first year including software, training, and consulting support for a mid-sized firm.

Can small startups afford simulation-first approaches or is it only for large corporations?

Small startups can absolutely adopt simulation-first design thanks to subscription-based software licensing and cloud computing. Many simulation vendors offer startup programs with reduced pricing. Cloud platforms eliminate the need for expensive hardware investments. Several successful startups build competitive advantages specifically through superior simulation capabilities that would have been impossible to afford a decade ago.

How long does it take to train engineers to use simulation software effectively?

Basic proficiency typically requires 3-6 months of regular use with formal training. Achieving expertise for complex multi-physics simulations takes 1-2 years. Most companies accelerate learning through vendor training programs, online courses, and mentorship from experienced simulation engineers. The learning curve is significant but manageable with proper support and realistic expectations.

What’s the biggest challenge companies face when transitioning to simulation-first design?

Cultural resistance represents the biggest challenge—not technical limitations. Engineers accustomed to physical prototyping may distrust simulation results initially. Success requires organizational buy-in from leadership, validation studies proving simulation accuracy, and patience as teams develop confidence in virtual testing. Technical challenges like software selection and training are solvable; changing engineering culture requires sustained commitment.

Related Topics: How to Make Handmade Wedding Cords for a Unique Ceremony

Related Topics: How Do You Describe a Marriage Ceremony?

References

- U.S. Department of Energy, Advanced Manufacturing Office. “High-Performance Computing for Manufacturing.” https://www.energy.gov/eere/amo/high-performance-computing-manufacturing

- Markets and Markets. “Engineering Simulation Software Market Global Forecast to 2027.” https://www.marketsandmarkets.com/Market-Reports/simulation-software-market-248876276.html

- National Institute of Standards and Technology. “Modeling and Simulation for Advanced Manufacturing.” https://www.nist.gov/programs-projects/modeling-and-simulation-advanced-manufacturing

- American Society of Mechanical Engineers. “The Impact of Simulation on Product Development.” https://www.asme.org/topics-resources/content/simulation-driven-design